Site supervisors in construction, surveying and similar settings continually assess many factors to manage labor requirements and keep projects under budget.

If you need abrasive blasting media for surface finishing, cleaning or other tasks, selecting the most appropriate solutions for individual jobs improves outcomes.

Reputable providers can align with your goals by suggesting efficient products sold at reasonable prices and in various quantities to suit specific tasks.

The best value abrasive for industrial applications depends on a project’s goals, but you can find many cost-effective options from these leading providers.

1. 10X Engineered Materials

10X Engineered Materials offers highly effective, science-based abrasive blasting products for numerous demanding markets, including heavy equipment, aerospace and agriculture.

Its offerings are unique because they include a mineral wool insulation by-product that makes them sustainable and one of the market’s safest options. These versatile sandblasting solutions can help remove contaminants, corrosion and coatings.

This premium abrasive blasting media generates low amounts of dust, increasing safety in the work environment by maintaining visibility.

Since these specially engineered materials are extremely effective, you can do more work with each container. Some are also suitable for blasting pressures of at least 130 pounds per square inch.

Customers requiring exceptionally tough solutions find many benefits in these superoxalloy abrasives.

Unlike conventional options, they include randomly arranged particles with tempered, amorphous characteristics that make them less likely to shatter on impact.

They also help leave the substrate clean and virtually free of embedded pieces that could cause rust bloom, giving you effective results.

Key Features

| This company sells the market’s only biosoluble abrasives, which are safe and often quickly cleared if inhaled. | 10X Engineered Materials products are cost-effective, making them ideal for projects with tighter budgets. |

| These options are among the fastest-acting in the industry and achieve a high-quality finish. | The company provides free technical support, allowing you to optimize results for individual applications. |

2. Black Diamond Abrasive Products

Black Diamond Abrasive Products offers high-performance solutions for industries ranging from shipbuilding to steel fabrication.

In addition to its coal and copper slag formulas, this provider sells numerous specialty abrasives, such as garnet and corn cob. This selection ensures you can find options to fit your budget and applications.

Product development specialists formulate these offerings with hard, angular particles that feature a uniform weight and gradation.

These choices give powerful results, allowing people to blast through several paint layers or tackle other tough tasks. However, Black Diamond Abrasive Products also has gentler varieties for delicate work, like glass etching.

Because the company’s abrasive blasting media has low-dust, chemically inert characteristics, it keeps your workforce safer and productive.

This provider also has a straightforward abrasive management program, so you can get products delivered as needed and removed for recycling upon request.

Key Features

| This brand has the industry’s largest assortment of grade sizes to achieve your target profile and finish. | The media is compatible with any blaster that has an appropriately sized nozzle, so you can use it with existing equipment. |

| Convenient online resources — such as nozzle sizing guides and product comparison guides — help you choose wisely. | The company’s abrasives are recyclable if you use them in clean environments and develop an effective screening process to recapture the granules. |

3. BlastOne

BlastOne operates in the United States and three other countries, giving it a wide reach to meet your abrasive blasting media needs. It provides specialty products and practical knowledge to address industry challenges.

This brand’s mission is to help professionals complete projects faster, safer and cleaner. These far-reaching benefits impact your bottom line by extending equipment longevity and raising worker satisfaction and retention rates.

BlastOne has become a leading option for abrasive blast media, blasting equipment and painting items. After becoming a customer, you can create an online account to quickly make repeat purchases or review outstanding invoices.

That resource helps you address administrative needs to keep your projects maximally productive.

If you are unsure which abrasive to use, BlastOne’s consultants can help you make appropriate decisions. They take a project-specific approach to suggesting solutions and will assess factors such as your desired finish, average productivity, and budget.

Key Features

| Customers can enjoy free shipping on orders over $100. | BlastOne’s handy Order Pad website feature allows you to add items to your cart in bulk by inputting the item numbers and quantities. |

| Credit accounts are available to qualified applicants. | An extensive online knowledge center features charts, buying guides, technical resources and other materials to help you make purchasing decisions. |

3. Kramer Industries, Inc.

Kramer Industries, Inc. is a highly respected, full-service provider of blasting, vibratory and parts-separating equipment. The company’s mission is to solve every surface-finishing problem, and it aims to be the first option professionals consider.

The extensive abrasive media selection includes plastics, pumice, melamine, walnut shells and much more. The company’s representatives will have thorough conversations with you to determine your needs before recommending options.

An available media recycling program allows you or a Kramer representative to send used media to a remanufacturing location, where it is cleaned, graded and packaged for reuse. This sustainable choice reduces your media disposal costs and makes your services more competitive to potential clients.

Key Features

| Kramer Industries, Inc. provides robust technical and administrative support to help you optimize outcomes. | All costs are clearly explained, with no hidden or tacked-on charges, ensuring you order quantities to match your budget. |

| A Right From The Start Guarantee represents the company’s commitment to absolute customer satisfaction and taking every possible action to fix situations when needed. | The company’s job shop can provide fixed, per-part finishing costs, giving efficient time frames and consistent results to supplement your workflow. |

4. Grainger

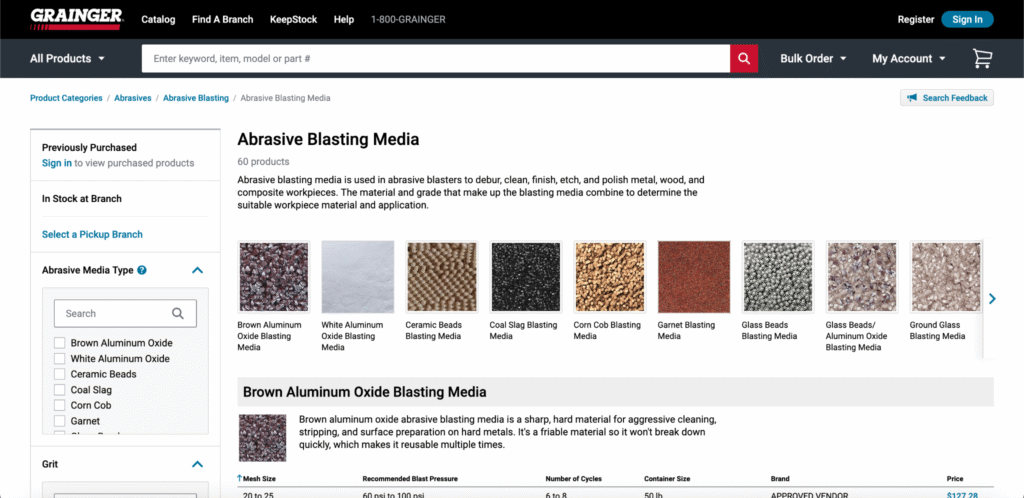

Grainger has nearly a century of history as an industrial supplier, offering more than a million products to help people maintain, repair and operate their equipment. The option to purchase online or pick up at one of over 250 branch locations lets you stay productive by getting your abrasive blasting media as quickly as possible.

Browse the abrasive blasting media assortment, which contains dozens of possibilities. Use the website filters to narrow the options, and then review the complementary tables to learn details, like media and container sizes.

Because each media type includes information about the different product variations and prices, you can quickly determine which ones fit your budget and other needs. There is also an option to select items that are immediately available for pickup.

Because this company provides delivery dates based on real-time product availability, you can expect accurate time frames that aid project planning. Once you have found offerings that work best for your applications, you can use Grainger’s auto-reorder service — a subscription-style benefit that ensures you will not run out.

Key Features

| Grainger offers 24/7 customer and technical support. | Next-day delivery is available on most orders to reduce workflow interruptions. |

| Customers can use the convenient mobile app and online services to replenish their supply anytime. | Grainger serves more than 3.5 million customers, illustrating its reputation as a trustworthy option. |

How to Choose the Appropriate Abrasive Blasting Media for Your Project

Thoughtfully selected abrasives can make you and your team more effective, achieve consistent results, and help you stay within budget. Here is what to consider when reviewing the leading options:

Application

People use abrasive blasting media in various industrial applications, such as stripping paint, removing mold, achieving a particular finish or adding beneficial surface characteristics. When determining the best products for your needs, start by examining the material’s toughness.

Crushed walnut shells are gentle and can remove topcoats without affecting the deeper layers. Conversely, aluminum oxide is one of the most aggressive possibilities. It is a practical choice for deep surface etching or paint removal.

Mismatches between the intended results and the chosen blasting media can damage surfaces or your equipment. Understanding the associated characteristics of potential varieties helps you make informed decisions.

Sustainability

Many companies offer abrasive blasting media made of recycled materials, like crushed glass. You can also purchase options made from typically wasted products, such as corn cobs.

That approach keeps resources out of landfills and helps you prioritize sustainable principles.

Some brands also offer recycling services and will pick up your used abrasives at specified times. This allows you to prioritize sustainability without needing to source a provider yourself.

Operating sustainably also extends to choosing abrasive blasting media that minimize environmental harm.

Some options are biodegradable, and you can find nontoxic products to use around areas frequented by wildlife.

Silicon carbide and aluminum oxide are two examples of abrasive blasting materials that can be reused many times before discarding them. This advantage saves money and is kinder to the environment than single-use options.

Cost

The size, shape and hardness of your blasting media can affect the price you pay. Some providers also offer bulk discounts, which are cost-effective if you know the media type you need and require it in large quantities.

However, remember to do more than find the lowest-priced products. A reliable provider can also keep costs down by suggesting products that give consistently excellent results.

Additionally, vendors often sell proprietary products formulated for particular outcomes. Finding a solution that meets all or most of your needs could save you the most money, even if it costs a bit more upfront.

Productivity

Many abrasive blasting media sellers combine coarse and fine grains in their mixtures, saving customers time and providing great results.

Similarly, some offerings break down less extensively than their competitors, resulting in less dust and debris. Those advantages enable better operator experiences and shorter cleanup times.

Blasting soda is a water-soluble solution that reduces the time required to tidy work areas after a shift.

Versatility is another aspect affecting suitability. Suppose an employee’s role requires working with various substrates during a typical day.

In that case, aluminum oxide is a good choice because of its compatibility with metal, glass, wood and other widely used materials.

Safety

Worker well-being is essential when evaluating different abrasive blasting media options, especially if employees are exposed for at least several hours daily. Low-dust formulas and those with no detectable silica are safest for the respiratory system.

Some blasting products also have inherent characteristics requiring special safety precautions.

For example, people handling dry ice must wear insulated gloves to prevent frostbite. Additionally, dry ice pellets become carbon dioxide as they hit surfaces. Employees using this method should work in well-ventilated areas to prevent asphyxiation.

Seller Support

Many companies selling abrasive blasting media have consultants who will take the time to learn about your in-depth needs and suggest suitable products.

Additionally, you can find complementary materials — such as specification sheets and videos — that help you get the best results from the chosen product.

Since satisfaction is the goal of most businesses, they may offer troubleshooting if you do not get the expected outcomes from your purchase.

As you evaluate the sellers on your shortlist, pay attention to factors such as years of experience and customer reviews. Strong testimonials from satisfied users can indicate that representatives will go above and beyond to assist.

Your projects may have additional particulars to evaluate as you choose the best solutions. However, application, sustainability, cost, productivity, safety and support are some of the top factors affecting time and money spent.

Methodology

The company list includes providers that can meet diverse industry requirements through experience, easy ordering options and extensive product assortments.

Benefits such as resource libraries, technical support and sustainability efforts were also considered because they make companies more applicable to today’s decision-makers.

What Is the Best Value Abrasive for Industrial Applications?

A product’s value encompasses more than what you pay for it. Overall performance and how well the product suits your application and equipment influence your outcomes.

If you need abrasive blasting equipment for a new project and are unsure how to proceed, consider asking representatives from the above companies to help you find appropriate solutions.

Once you have selected an option, ask your team for feedback to see how well it saves time and fits your budget.

Also Read

Choosing the Right Abrasive: A Buyer’s Guide for Industrial Use

Safety and Handling Tips for Working with Aluminum Oxide Abrasives